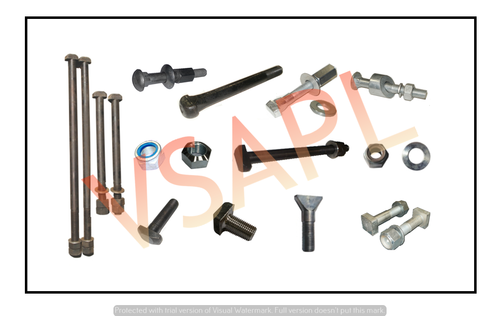

Bolts for Crushers

Product Details:

- Diameter 16 mm to 56 mm

- Drive Type Hex Head

- Noise Level Silent (no noise generation)

- Size M16 to M56 (Length as per requirement)

- Usage & Applications Used for fastening and securing crusher machine parts, jaw plates, side plates, liners, and other crusher assemblies

- Product Type Crusher Bolt

- Material High Tensile Steel

- Click to view more

X

Bolts for Crushers Price And Quantity

- 1 Piece

Bolts for Crushers Product Specifications

- High Tensile Steel

- Crusher Bolt

- 16 mm to 56 mm

- Hot Forged

- Customized as per size

- Zinc Plated / Hot Dip Galvanized

- Used for fastening and securing crusher machine parts, jaw plates, side plates, liners, and other crusher assemblies

- M16 to M56 (Length as per requirement)

- Silver, Black

- Silent (no noise generation)

- Hex Head

- Mechanical

- Varies as per design/specification

Bolts for Crushers Trade Information

- Cheque

- 8 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Carton Boxes.

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Delhi

Product Description

Experience the exclusive performance of our must-have Bolts for Crushers, expertly engineered for the toughest industrial demands. Crafted from potent high tensile steel using hot-forging technology, these bolts deliver phenomenal strength and durability at an affordable price point. With astounding surface treatments such as zinc plating or hot dip galvanizing, each bolt ensures maximum corrosion resistance. Sourced, manufactured, and exported from India, these mechanical power-sourced bolts are available in a range of sizes (M16-M56) and colors (silver, black) to fit crusher jaw plates, side plates, liners, and more, all while ensuring a silent, secure hold.

Precision Fastening for Crusher Assemblies

Bolts for Crushers are specifically designed for securing and fastening essential crusher machine parts, including jaw plates, side plates, and liners. This potent solution ensures machine components remain firmly in place during operation, both for specific crusher appliance applications and general heavy-duty industrial use. Application involves aligning the bolt through pre-drilled holes in the assembly and using a hex-head drive for optimal tightening, providing stability and extending machine lifespan.

Swift Dispatch & Certified Quality

Our bolts undergo stringent packing & dispatch processes to guarantee protection during transportation. We offer transparent list pricing and flexible payment terms tailored to your requirements. Orders are typically dispatched promptly, with delivery times varying by location and quantity. Each batch of bolts comes with relevant certifications, ensuring compliance with international quality standards and reinforcing our reputation as preferred exporters, manufacturers, suppliers, and traders from India.

Precision Fastening for Crusher Assemblies

Bolts for Crushers are specifically designed for securing and fastening essential crusher machine parts, including jaw plates, side plates, and liners. This potent solution ensures machine components remain firmly in place during operation, both for specific crusher appliance applications and general heavy-duty industrial use. Application involves aligning the bolt through pre-drilled holes in the assembly and using a hex-head drive for optimal tightening, providing stability and extending machine lifespan.

Swift Dispatch & Certified Quality

Our bolts undergo stringent packing & dispatch processes to guarantee protection during transportation. We offer transparent list pricing and flexible payment terms tailored to your requirements. Orders are typically dispatched promptly, with delivery times varying by location and quantity. Each batch of bolts comes with relevant certifications, ensuring compliance with international quality standards and reinforcing our reputation as preferred exporters, manufacturers, suppliers, and traders from India.

FAQs of Bolts for Crushers:

Q: How do I select the right size of bolts for specific crusher assemblies?

A: You should consider the dimensions and requirements of your crusher components. Our bolts come in diameters from 16 mm to 56 mm, with customizable lengths to match the exact design specifications of jaw plates, liners, and other parts.Q: What is the process for applying these bolts during installation?

A: Align the bolt with the pre-drilled holes of the crusher assembly, insert it, and securely tighten using the hex head drive. This ensures a firm, silent, and vibration-free hold.Q: When will my order be dispatched after placing it?

A: We aim for prompt packing & dispatch after order confirmation. Delivery time depends on order volume and location; our team will communicate expected lead times during purchase.Q: Where are these bolts manufactured and distributed from?

A: Our high tensile steel bolts are manufactured, packed, and dispatched from our facilities in India, ensuring easy export to various global markets.Q: What are the key benefits of using high tensile steel, hot-forged crusher bolts?

A: High tensile, hot-forged steel bolts offer phenomenal toughness, astounding durability, and superior resistance to corrosion, ensuring a potent and reliable fastening solution for critical crusher assemblies.Q: How does zinc plating or hot dip galvanizing enhance the bolts performance?

A: Both zinc plating and hot dip galvanizing provide a resilient coating that combats rust and wear, thereby extending the operational lifespan of each bolt even in harsh environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email